Vollrath 15059 Bruksanvisning

Vollrath

kuttemaskin

15059

Les nedenfor 📖 manual på norsk for Vollrath 15059 (12 sider) i kategorien kuttemaskin. Denne guiden var nyttig for 12 personer og ble vurdert med 3.9 stjerner i gjennomsnitt av 6.5 brukere

Side 1/12

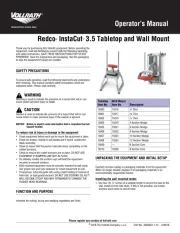

Operator’s Manual

Redco

®

InstaCut

™

3.5 Tabletop and Wall Mount

©

2016 The Vollrath Company L.L.C. Part No. 2350022-1 ml 2/26/16

Please register your product at Vollrath.com

Thank you for purchasing this Vollrath equipment. Before operating the

equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE. Save the original box and packaging. Use this packaging

to ship the equipment if repairs are needed.

SAFETY PRECAUTIONS

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

Warning is used to indicate the presence of a hazard that will or can

cause severe personal injury or death.

Caution is used to indicate the presence of a hazard that will or can

cause minor or major personal injury if the caution is ignored.

NOTICE: Notice is used to note information that is important but not

hazard-related.

To reduce risk of injury or damage to the equipment

• Check equipment before each use to insure the equipment is clean.

• Check for broken, nicked or dull blades and if found, replace the

blade assembly.

• Check to insure that the pusher head sits down completely on the

rubber bumpers.

• Check to ensure the rubber bumpers are in place. DO NOT USE

EQUIPMENT IF BUMPERS ARE NOT IN PLACE.

• On tabletop models the suction cups will hold the equipment

securely to smooth surfaces.

• Wall mounted equipment must be securely mounted to wall studs.

Use proper size and type hardware to mount equipment to wall.

• If necessary, lubricate guide rods using a light coating of mineral oil,

Petro Gel, or food grade lubricant. DO NOT USE COOKING OIL AS IT

WILL BECOME STICKY AND MAY PERMANENTLY DAMAGE THE

PUSHER HEAD BEARINGS.

FUNCTION AND PURPOSE

Intended for cutting, dicing and wedging vegetables and fruits.

UNPACKING THE EQUIPMENT AND INITIAL SETUP

Carefully remove crating or packaging materials from the equipment.

When no longer needed, dispose of all packaging materials in an

environmentally responsible manner.

Installing the wall mounted model

1. Use four (4) ¼" screws of a suitable length to secure the base to the

wall. Install screws into studs. If this is not possible, use proper

anchors and screws to secure base.

WARNING

CAUTION

Tabletop

Item No.

Wall Mount

Item No. Description

15000 15016 ¼" Dice

15001 15017 " Dice³⁄₈

15002 15018 " Dice½

15003 15019 4 Section Wedge

15005 15021 6 Section Wedge

15006 15022 8 Section Wedge

15007 15023 10 Section Wedge

15008 15024 12 Section Wedge

15009 — 6 Section Core

15010 15026 8 Section Core

Produkspesifikasjoner

| Merke: | Vollrath |

| Kategori: | kuttemaskin |

| Modell: | 15059 |

Trenger du hjelp?

Hvis du trenger hjelp med Vollrath 15059 still et spørsmål nedenfor, og andre brukere vil svare deg

kuttemaskin Vollrath Manualer

23 August 2025

23 August 2025

23 August 2025

22 August 2025

11 August 2025

11 August 2025

kuttemaskin Manualer

- Nemco

- Gastronoma

- Dito Sama

- Beem

- Magimix

- Prince Castle

- Axis

- Electrolux

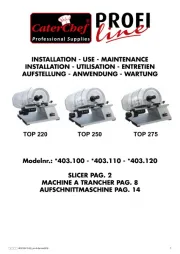

- CaterChef

- Doyon

- Oster

- Zelmer

- Gourmetmaxx

- Ariete

- Wilfa

Nyeste kuttemaskin Manualer

10 Oktober 2025

8 Oktober 2025

7 Oktober 2025

7 Oktober 2025

7 Oktober 2025

7 Oktober 2025

2 Oktober 2025

30 September 2025

30 September 2025

29 September 2025